Residents can use their Scarsdale Llibrary Card to submit 3D files online to be 3D printed by library staff! This is a free service, with a limit of one file per resident per week. It may take up to 1 week from date of submission to receive confirmation that your file has been approved and added to the queue, and up to 2 weeks from date of submission for your item to be ready for pickup. SPL cannot guarantee that items will be printed by a specific requested date. You will receive an email notification when items are ready to be picked up at the reference desk.

The library is currently only printing using white PLA, or polylactic acid, a strong and nontoxic biodegradable material.

Files must meet the following requirements:

- Must be submitted as an .STL file

- Must have an expected print time of no more than 4.5 hours, or 270 minutes, including added time for support and adhesion structures

- Must fit within a printable area of 180×180×180 mm

- Must adhere to our Terms of Use.

If your file meets all these requirements, submit it here! Or, keep scrolling for a step by step process.

Feel free to contact us at makerspace@scarsdalelibrary.org with any additional questions. Allow up to one week to receive a reply as our makerspace staff is currently limited.

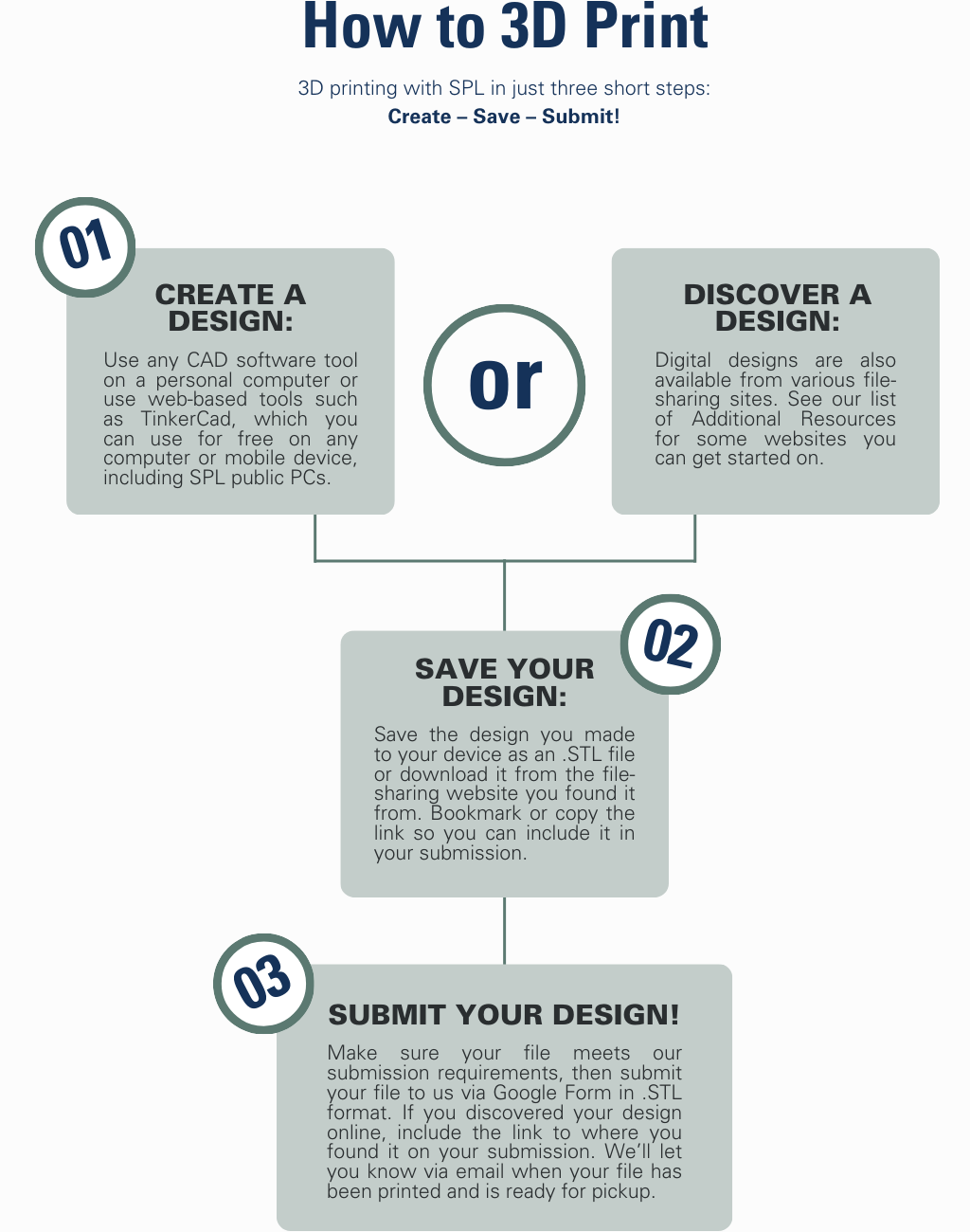

View this flowchart as plain text here.

Submission Requirements

- Designs must be submitted via Google Form in the .STL format.

- Files may be no larger than 100MB.

- Files must have an estimated print time of no more than 4.5 hours (270 minutes) or they will not be printed.

- Items must fit within our base plate printable area of:

- 180mm long

- 180mm wide

- 180mm tall.

- Files must adhere to our Terms of Use.

For guidance on meeting these requirements, see Tips and Tools.

Submission Procedures

- Items will be printed as demand allows on a first come, first served basis.

- Makerspace library staff will notify patrons via email when items are complete. Patrons will be informed of design issues and changes required for printing.

- The library reserves the right to dispose of or re-purpose any printed items not picked up within 2 weeks of notification.

- The library does not guarantee print results.

- The Library will review all files before printing.

- Makerspace staff may assist patrons with submitting their design and adhering to Library requirements correctly, but the final responsibility for the design rests with the patron.

- Files will be printed in white PLA.

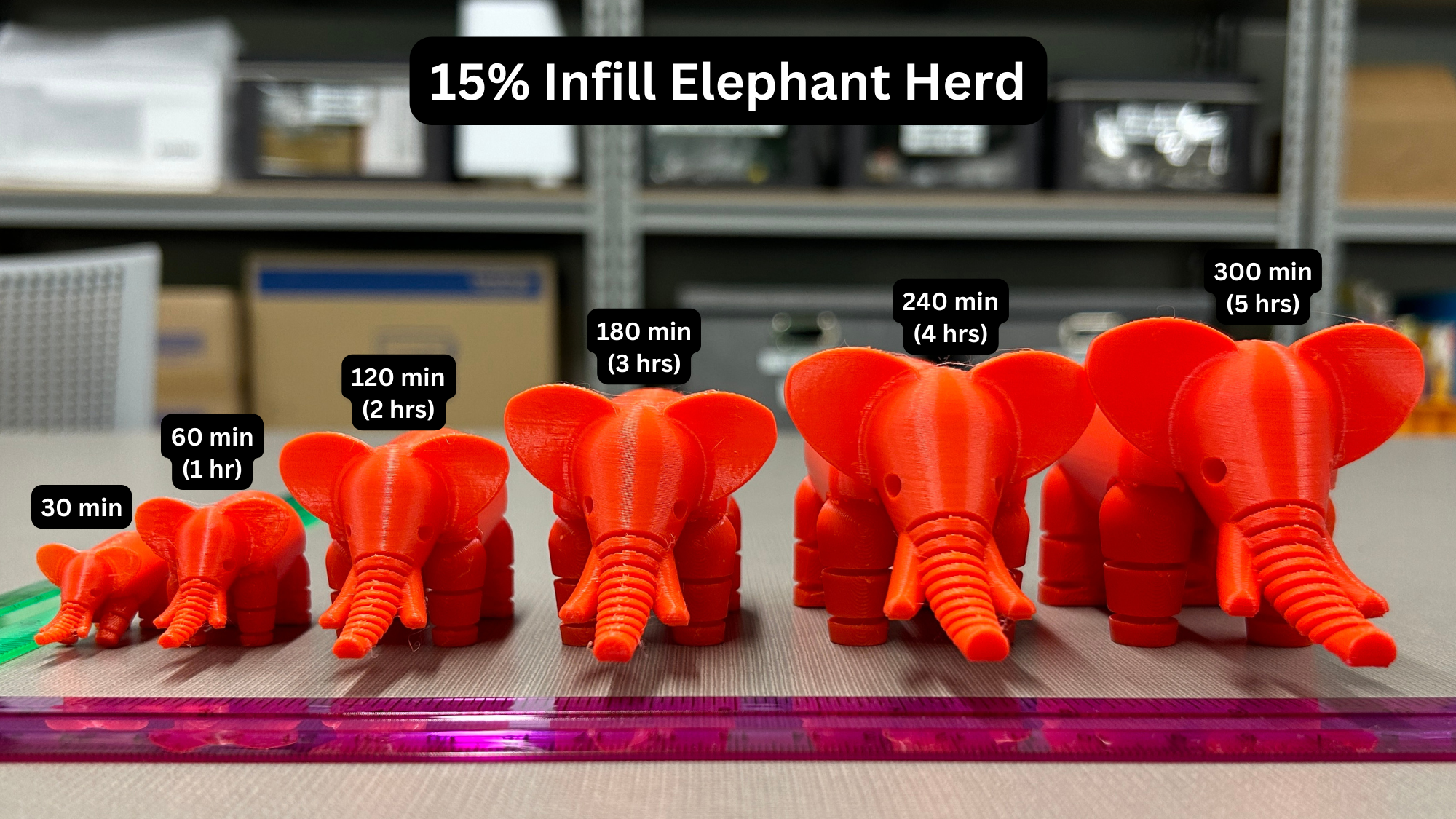

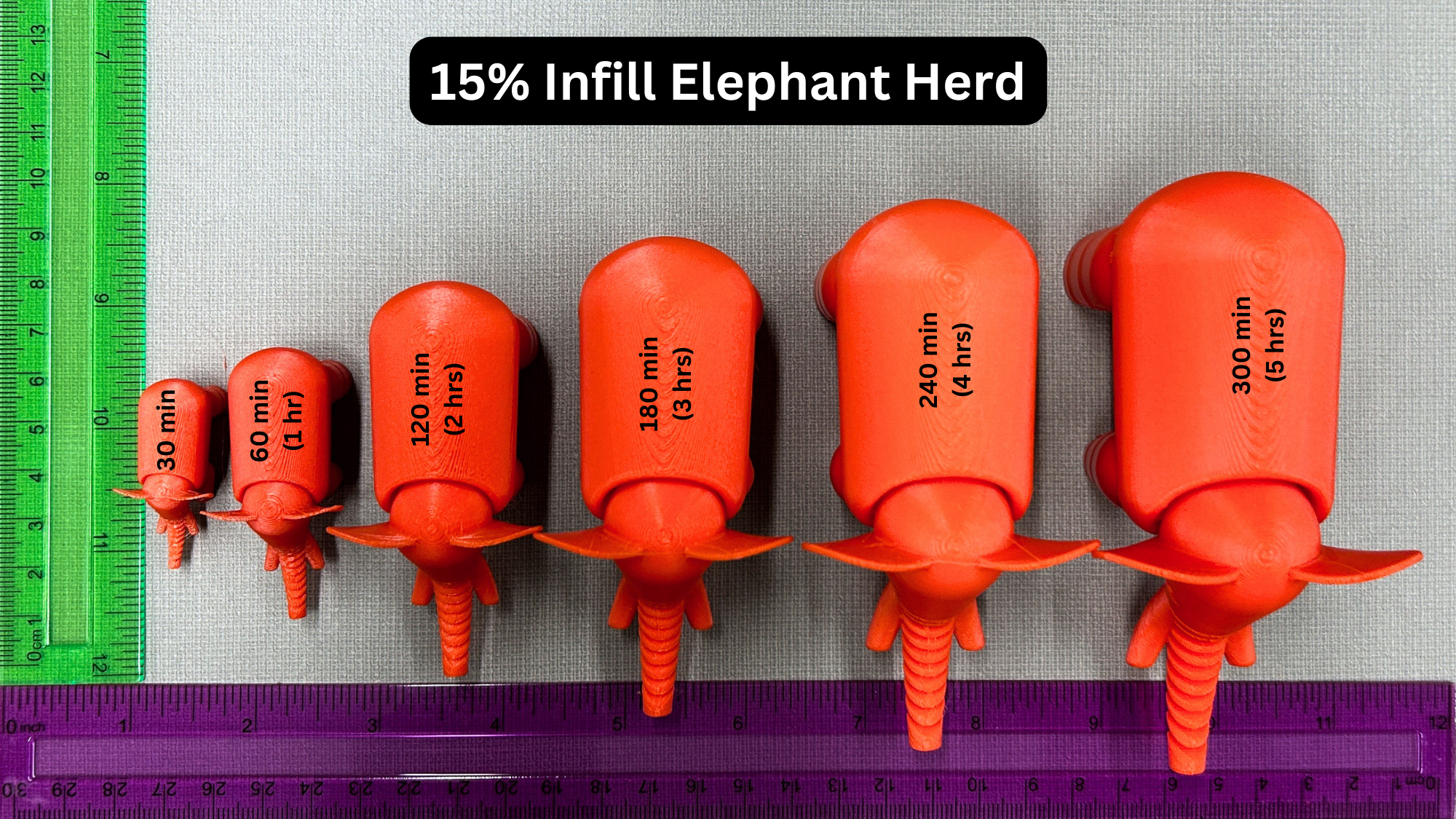

- Files will be printed at 15% infill unless otherwise requested.

Tips and Tools for Printing

Submitting a printable file

- Due to the type of filament the library uses, PLA, the library does not recommend using 3D printed parts from the SPL makerspace in environments with high temperatures, chemical solvents, for cooking, or being subjected to torque and stress.

- To ensure that your file is not too large for our printer, use this, a helpful resource that checks your file’s measurements: 3dviewer.net.

- The library is only able to print files that take under 4.5 hours (270 minutes) to print. If you are uncertain how long your project will take, email the file to makerspace staff at makerspace@scarsdalelibrary.org and it will be checked for you.

- Makerspace staff can resize oversize items to fit on the printers and within the print timeframe. If you would like this option, you can select it when uploading your file to our file submission form. This option is only recommended if your file is a standalone item that is not designed to fit together with any other pieces (like other 3D printed parts, screws, or bolts). OR

- You can use slicing software such as PrusaSlicer to generate an estimate. For most accurate results, set the printer to Original Prusa Mini & Mini+ and filament as generic PLA.

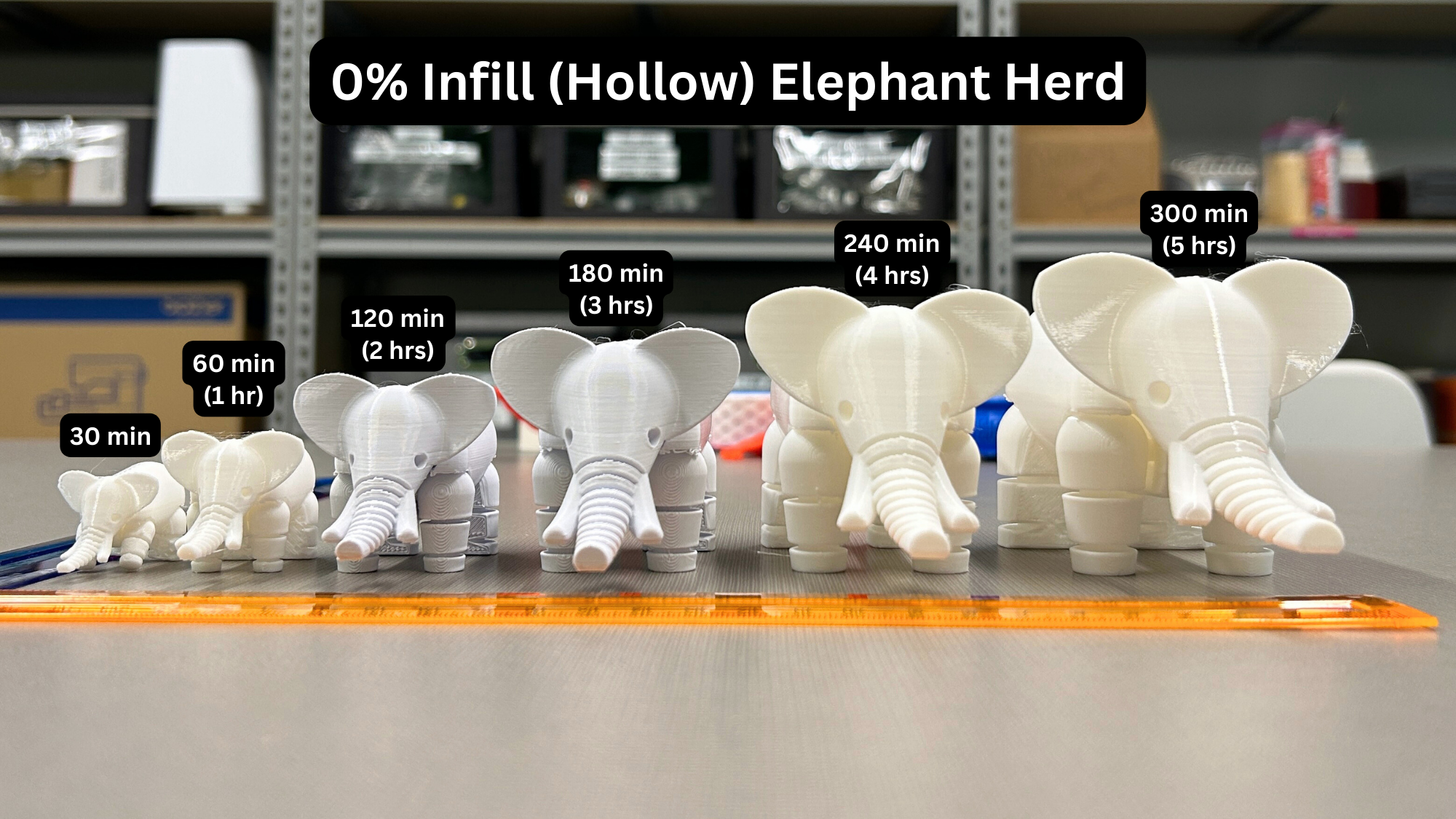

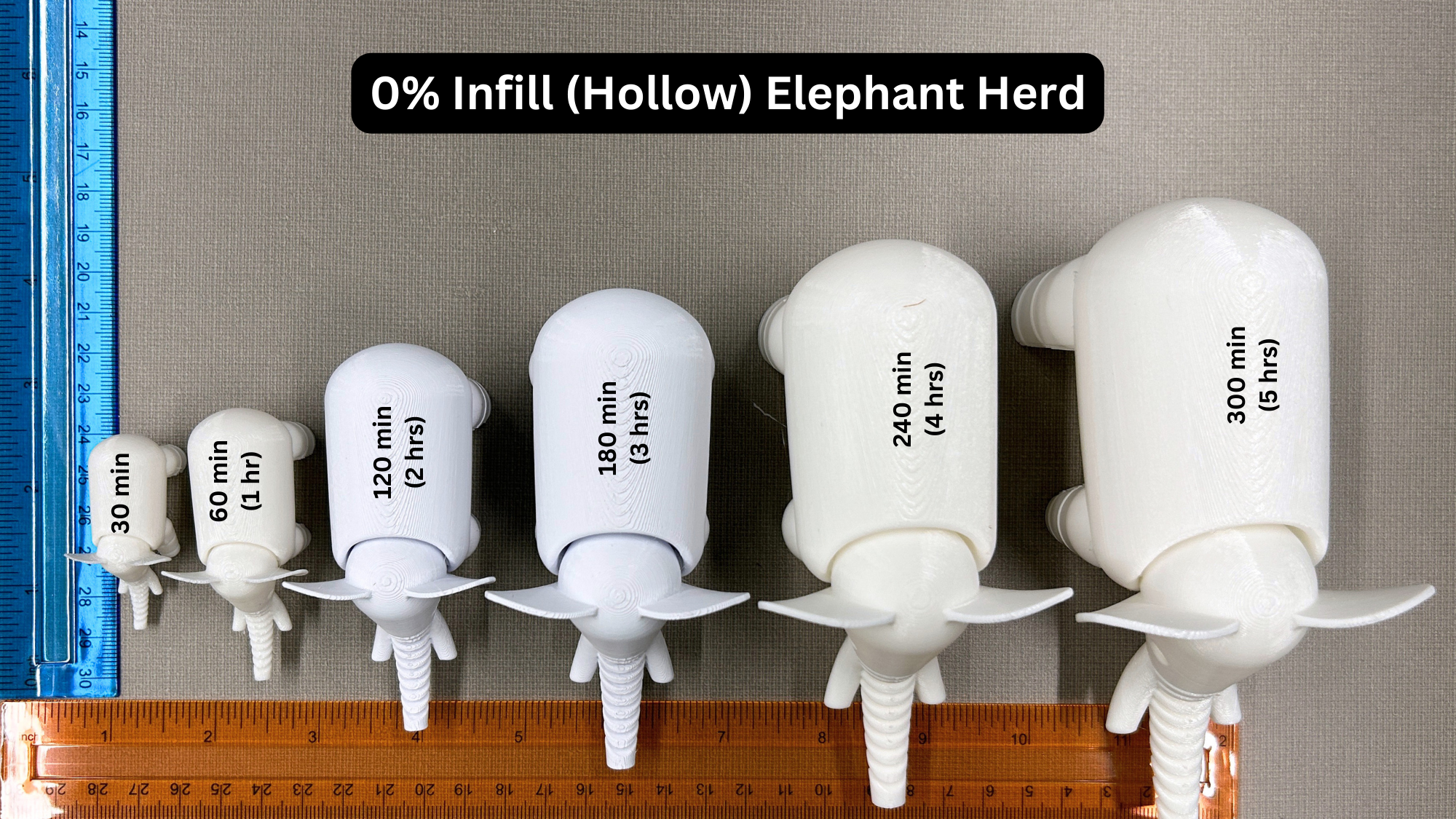

To help you get a sense of the correlation between object size and print times, our elephants are here to help! Each elephant is labeled with its respective print time. The orange elephants on the left are printed with a standard 15% infill, which adds support to the elephants, but takes longer to print. The white elephants on the right are printed at 0% infill and are completely hollow inside.This results in larger printed elephants than their orange counterparts in the same time frame. Makerspace staff will print at 15% infill by default, but if you have a design that's optimized to be printed hollow (or any other infill), you can indicate it on the submission form.

Getting the best result

Our printers are fused deposition modeling (FDM) style 3D printers. This means plastic filament is fed into a heated nozzle that moves back and forth, depositing layers of plastic on top of one another. This style of printer generally prints better when an object is bigger along the bottom and gets smaller at the top (like a pyramid).

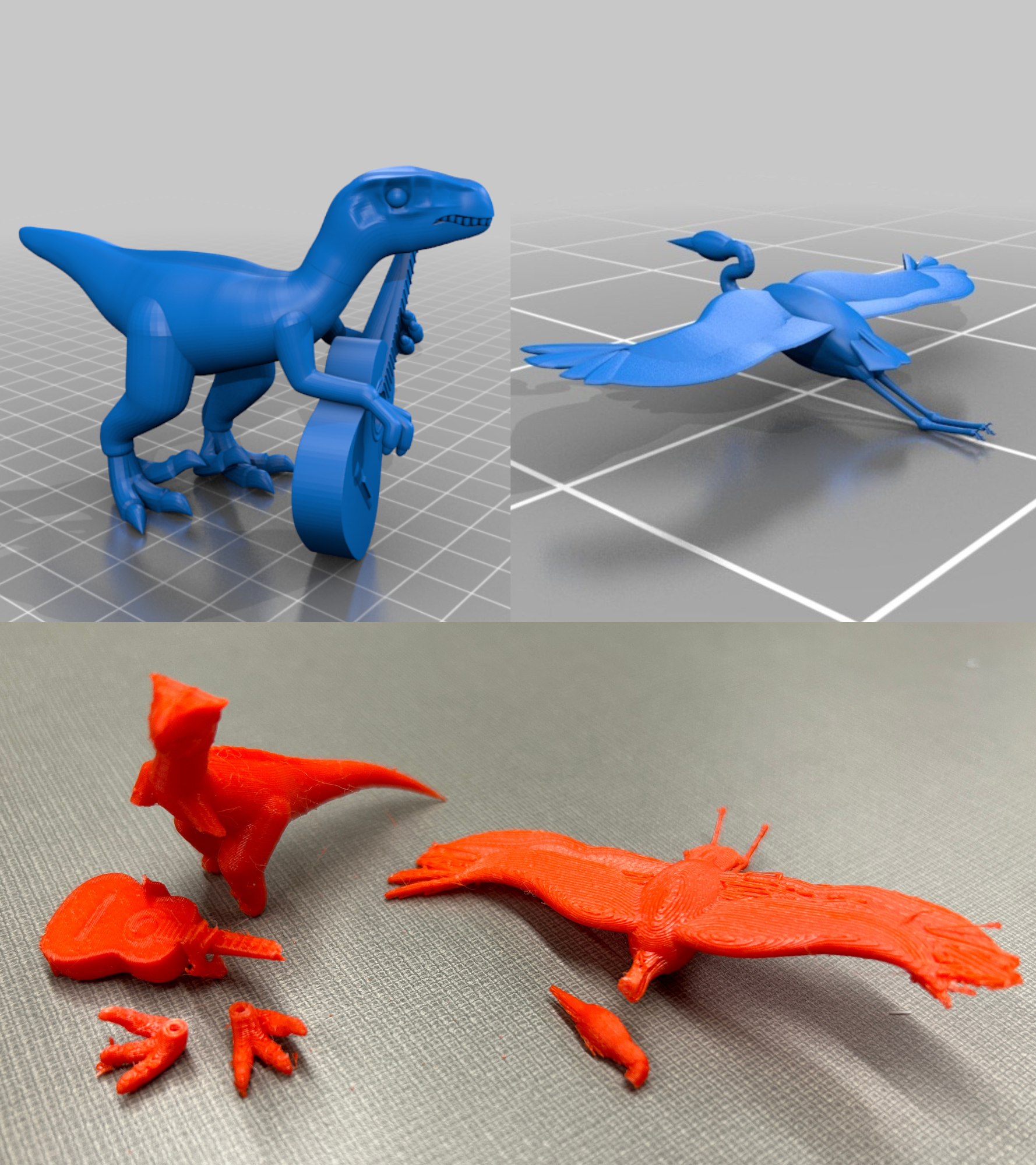

Complex shapes and small details (like wings, teeth, or small lettering) may not print exactly how you see them on your screen. Shapes with very thin connection points are also at risk of bending or snapping.

Choosing and designing simpler shapes will help you have a more successful print.

Successful Prints

Difficult Prints

About Our Printers

The SPL makerspace uses Prusa Mini 3D printers, fused deposition modeling style printers with Bowden extruders and a build plate printable area of 180×180×180 mm. At this time the SPL makerspace uses only polylactic acid (PLA) filament in our printers. This article gives a useful overview of the basic properties of PLA filament and its uses. The library does not recommend using 3D printed parts from the SPL makerspace in environments with high temperatures, chemical solvents, for cooking, or being subjected to torque and stress. Regarding color options, SPL currently offers white.

Additional Resources

There are tons of file sharing websites available online. Some of the ones we recommend are:

- Thingiverse – the most popular free 3D print file sharing platform. Great for just starting out and looking for inspiration.

- Printables – similar to Thingiverse, also free.

- STLFinder – a search engine that checks all 3D repositories for free results. A great tool if you’re looking for something specific.

- Cults – pay-to-download high quality 3D print files made by independent artists. Note that this is not a free option.

There are a variety of 3D modeling (CAD) software options available that are worth exploring as you get more comfortable with 3D modeling. Here are three free and approachable options for starting out:

- Tinkercad – a free browser based 3D modeling software. A great entry point for beginners.

- Sketchup Free – browser based 3D modeling software mostly used by architects, but the free version is also a great introductory option for 3D printing.

- Fusion 360 Free– professional quality 3D modeling software. The free version offers a wide range of functions and is available for download.

We hope to start offering introductory Tinkercad workshops at SPL soon! In the meantime, all three of the platforms we suggest have built in tutorials. There are also lots of video tutorials online. Try searching for beginner tutorials plus the name of the software you’re trying to learn on Youtube.

Check the size of your design by uploading your STL file to 3dviewer.net To fit on our printers, make sure your print is less than 180 mm long, tall, and wide.

The best way to get a print time estimate is by using a 3D slicer, which takes an STL file and turns it into individual layers that the printer will print from bottom to top. We use PrusaSlicer, the companion software to our Prusa Mini printers. PrusaSlicer is free to download and use if you’d like to generate a time estimate for yourself. Note that support materials and infill percentage (how hollow the print will be) will affect the print time. Adjust these settings for yourself in PrusaSlicer to see how the estimates change. For most accurate results, set the printer to Original Prusa Mini & Mini+ and filament as generic PLA. Other slicers are available for free use, but may not be as accurate.

You can also always email us your file at makerspace@scarsdalelibrary.org and we will check for you.

Remember your file must take no longer than 4.5 hours (270 minutes) for us to print it.

Allow up to 1 week from date of submission to receive email confirmation that your file has been approved and added to the print queue. If your file is not approved, you will be informed via email. Allow up to 2 weeks from date of submission for your print job to be completed. You will be notified by email when your print job is ready for pickup or if any issues were encountered by makerspace staff while printing your file.

Terms of Use

- Any printing of firearms or components of firearms are prohibited.

- The Library reserves the right to refuse the production of any file at any time at the discretion of library staff including:

- Objects that the patron does not have a legal right to possess.

- Any object prohibited by the terms of use of the manufacturer of the 3D printer.

- By submitting designs for printing, the patron is representing that they are the owner or authorized user of the 3D design. The Library is not responsible for any third party infringement claims of patent, trademark, or copyright.

- 3D Printing at the library is currently free. Fees may be charged in the future to cover the printing costs. Users will receive notice of this change in advance.

- Patrons may not provide their own printing filament.

- Only designated library staff or volunteers may operate the 3D printer.

- The Library cannot guarantee model quality, stability, confidentiality of designs, or specific completion dates.

- Use of the 3D printer by Library staff does not constitute knowledge or acknowledgement of any unapparent final use of the 3D product, and the Library specifically disclaims any knowledge thereof.

- Print requests are limited to one item per week and one print per design.

- Print files will be deleted after the print is completed.

- This service is currently available to Scarsdale residents only.